Do you ever see a sneak peek of an upcoming pattern and start drooling? That's what happened to me when I saw the True Bias Darla Jumpsuit and Dress on Instagram. That back! So strappy and fun!

This garment took me forever to sew. The pattern came out right before we had to temporarily move into an AirBnb due to a tree fall on our home. I decided it would be a good project to take with me, so I started sewing it there. But then I needed my serger too. And then my dog died. And then a general depression took over my life and I stopped sewing.

It took me a month to get back to Darla. Per usual, an upcoming event pushed me to finish it. Nothing crazy, just a planned date night. And once she was done, oh my...I LOVE it!

The fabric I used is making me scratch my head. I THINK that it's the black version of the pink Lyocell/rayon/linen/cotton I used for this Willamette Top. I distinctly remember making a special trip to a different Jo-Ann's to get it. I have the receipt. But the receipt does NOT say that's what it is. It's a similar weight and it does have a slight shine with pressing, so it's unlikely that it's 100% linen or cotton. Anyway, it's very soft, slightly drapey, and lightweight. I like it a lot and it gathered well. The bodice is fully lined (as well as interfaced at the top) and I think that my fabric needed that extra support.

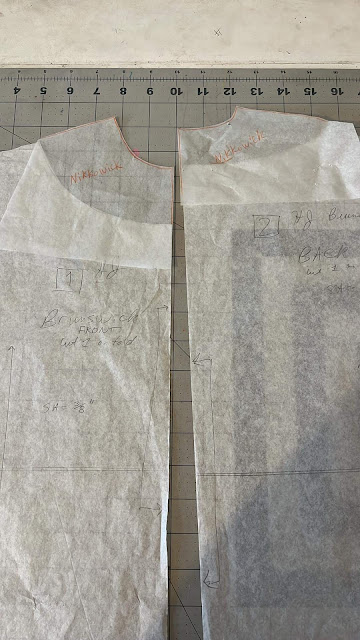

I made a size 2 top and a size 8 bottoms. It is extremely easy to mix sizes top and bottom, because the back is gathered with elastic (or just gathered into the back bodice if you use the zip up view) and the front pant (or skirt) is gathered into the bodice as well. I ended up shortening the back elastic quite a bit but that could be personal preference.

The instructions are excellent and there is a sew along if you need more help. The only part that confused me was the back elastic casing. Sometimes you fold the casing completely inside and sometimes it's visible from the outside...I couldn't tell which I was supposed to do. I checked the sew along and noticed that the print for the casing was different than the back pant/skirt and therefore was visible from outside.

If you make the strappy back view, everything lines up super neatly and is nicely enclosed. There is stitching in the ditch, which I hate, but you could also secure the bodice lining by hand if you weren't in the hurry that I was.

The pockets are in-seam but are constructed so that they sit inside the pant better than regular inseam pockets. They are also secured at the waistline so they do not sag.

I did feel like my pants were too short when it came time to hem. I probably cut them wonky because I'm not that tall (5'4") but maybe double check the inseam. I ended up adding a wide 2" cuff to each pant hem. It gives them a bit more weight and swish and I'm not mad at it. Especially in black because you can barely tell.

I can't believe this pattern isn't more popular. I have to believe that the back discourages regular bra-wearing and that throws people off. I tried it without a bra and if the bodice fits well (mine did) it gave a decent enough amount of lift. Again, mine being black hides a lot. In these photos, I'm wearing a stick on bra from Amazon, which worked fine as long as I also kept the straps pretty tight.

I definitely want to make the dress version of this pattern, probably in a rayon woven.

HIGHLY recommend you pick up Darla and make yourself some swishy goodness!